Special finishes course – embossing and debossing

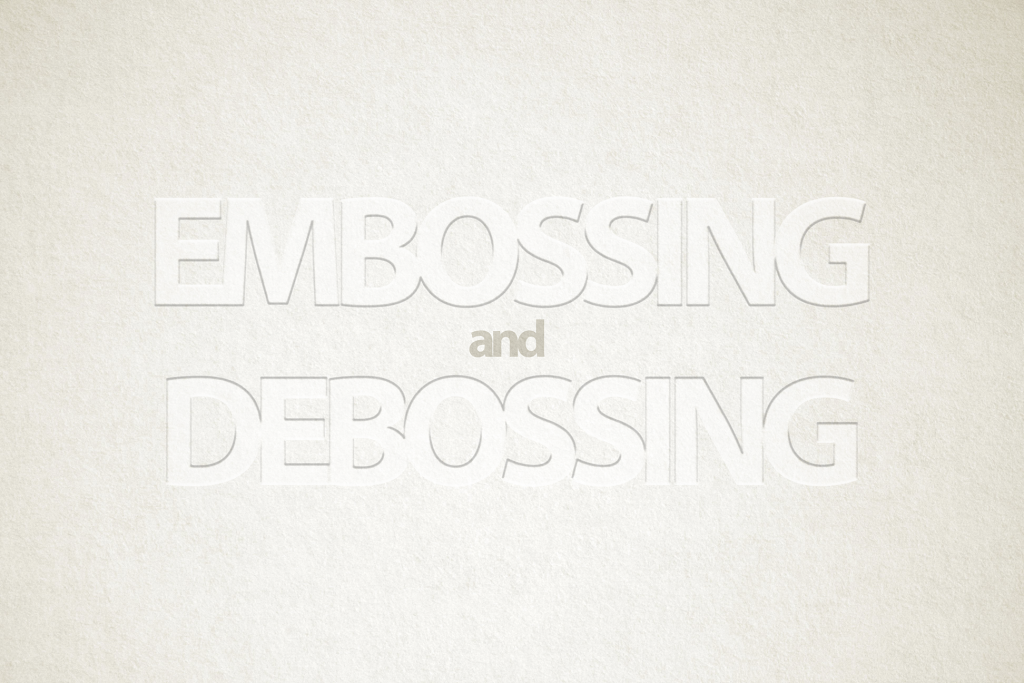

Embossing and debossing

Embossing involves pressing a metal tool to the underside of paper in order to create raised areas and debossing involves pressing the tool on the top of paper to create recessed areas.

Things to consider

- Use a 100% spot colour tint for embossed or debossed elements.

- Embossed or debossed elements must be hard edged and should not contain any gradients or feathering.

- All embossed or debossed elements should be set to overprint.

- Very fine details cannot be maintained. The minimum recommended stroke weight for fine details is 1pt.

- Blind embossing or debossing fine details has a 2pt minimum recommended stroke weight. This is because the lack of printed ink defining the shape creates a less detailed look.

- Cracking and flattening can occur in embossed or debossed areas closer than 6 mm from the trimmed edge, folds or 10mm from the cover pinch/hinge/divet area.